Services

PowerTech Energy Solutions is the service provider to the facilities/offices spaces. It is the result of hardcore professionals getting together to launch a venture.

Energy is a significant expense for any organization, and conducting an energy audit and management is essential to optimize energy usage, reduce costs, and achieve carbon emission reduction. Our BEE Certified Energy Auditors conduct comprehensive energy audits to identify areas of energy waste, inefficiencies, and opportunities for improvement.

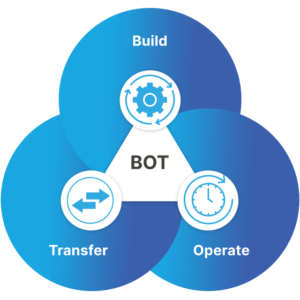

Energy Saving Contracts on a Build-Operate-Transfer (BoT) model can help businesses reduce their electricity bills without any upfront investment. These contracts are designed to implement zero investment or no investment energy saving projects, where the cost of the project is financed by the energy savings achieved over time.

Power quality is a critical aspect of any electrical system. Conducting a power quality audit and harmonic study is essential to ensure that your electrical system is functioning efficiently and effectively. The Institute of Electrical and Electronics Engineers (IEEE) has set standards for power quality compliance, including the IEE 519-2014.

Fire safety is a critical aspect that every business owner must prioritize. Conducting a fire safety audit is essential to identify potential hazards and ensure that your building complies with fire safety regulations. The National Building Code of India (NBC) 2016 and the National Fire Protection Association (NFPA) have set standards for fire safety compliance.

Earth Pit Resistance Measurement is a critical aspect of electrical safety measures in industries and commercial buildings. It involves testing the earth pit’s resistance to ensure it is functioning correctly and providing proper grounding.

A low earth pit resistance ensures effective protection against electrical hazards such as electrocution, equipment damage, and fire.

Electrical safety is critical for any workplace, and conducting an electrical safety audit is essential to ensure compliance with regulations such as the CEA Regulations 2010, NBC 2016, and NEC 2023 India. These regulations mandate the implementation of proper electrical safety measures to prevent electrical accidents and hazards.

For your better tomorrow, save energy today.

As a member of Mother Earth it is our duty to focus on energy conservation. To know the importance of energy saving, we must follow practical tips of how to save energy. We PowerTech Solutions believes in “Save Energy Save Earth” and “Conserve to Consume”.

Energy conservation is a crucial aspect of sustainable living. It refers to the practice of using less energy or finding ways to reduce energy consumption. Energy saving is essential for a variety of reasons, including the conservation of natural resources, reduction of carbon emissions, and cost savings.

One of the main reasons why energy saving is essential is the conservation of natural resources. Fossil fuels, such as coal and oil, are finite resources that are being depleted rapidly. These resources take millions of years to form, and we are using them up at an alarming rate. By conserving energy, we reduce our dependence on these non-renewable resources and ensure their availability for future generations.

Another critical reason why to save energy is the reduction of carbon emissions. Fossil fuels are a significant source of carbon emissions, which contribute to climate change. By reducing energy consumption, we decrease the demand for fossil fuels, thereby reducing carbon emissions. This, in turn, helps to mitigate the impacts of climate change, such as rising sea levels and more frequent natural disasters.

Finally, to save energy is essential because it can result in cost savings. By using less energy, we reduce our utility bills, which can save us a significant amount of money over time. Additionally, many energy-saving measures, such as installing energy-efficient light bulbs to save electricity or upgrading to energy-efficient appliances, can pay for themselves through the savings they generate.

To save energy, there are many practical steps we can take. For instance, we can use power saver devices, turn off lights and electronics when they are not in use, adjust our thermostats (a good example of Energy Management System) to use less heating or cooling, and switch to energy-efficient light bulbs. We can also reduce our water usage by taking shorter showers, fixing leaks, and installing low-flow showerheads and faucets. Another way to save energy is to upgrade to energy-efficient appliances, such as refrigerators, washing machines, and air conditioners.

In conclusion, energy conservation is crucial for sustainable living. By conserving natural resources, reducing carbon emissions, save energy, save electricity and saving money, we can make a significant impact on the environment and our wallets. Through simple actions like turning off lights, adjusting thermostats, and upgrading appliances, we can all do our part to save energy and protect the planet.